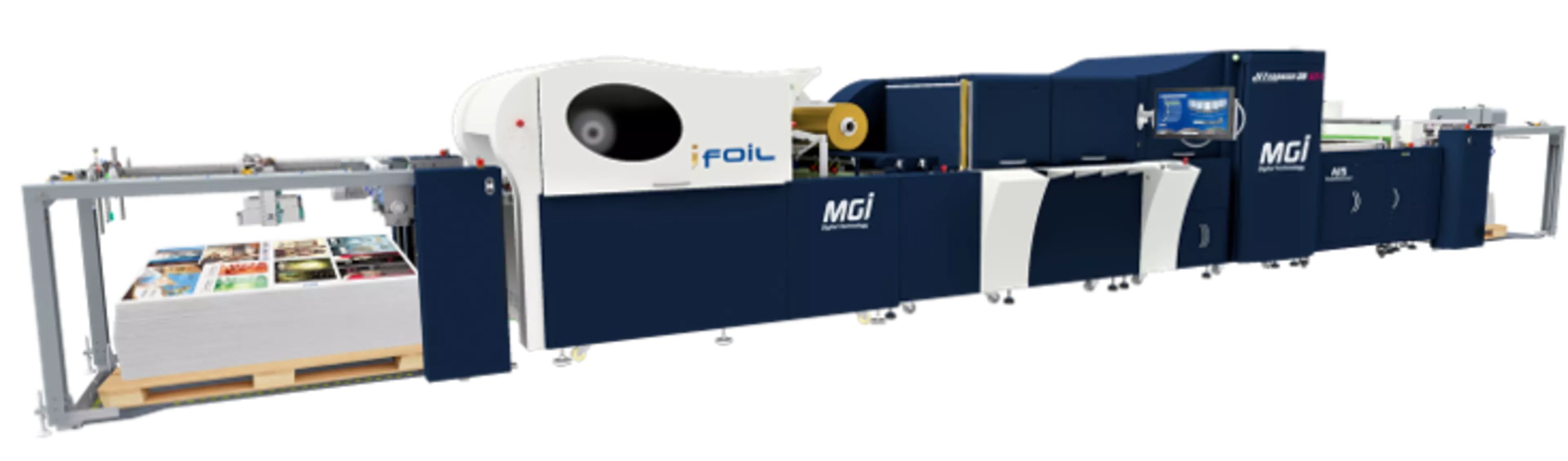

Printing technology | MGI’s exclusive inkjet engine technologyDrop-on-Demand (DOD) inkjet applicationPiezoelectric printheads in single pass printingFlexible and scalable architecture |

Variable coatingthicknesses | Depending on your file and the substrate used, the coating thicknesscan vary from a traditional flat spot UV coating of 7 μm up to232 μm for 3D raised texture effects and a tactile finish. |

Production speed(1) | Up to 3,123 B2 sheets size per hour (flat spot UV coating or 2D) |

Registration | Left and right motorized registration side guides. Automatic registrationusing the built-in AIS SmartSanner technology for real-timemanagement of entire sheet. No registration marks required.Overall registration of ± 200 μm. |

Managed paperformats(2) | Min.: 42 x 29.7 cm / 16.5” x 11.5” (A3 in landscape mode)Max.: 57 x 120 cm / 22.4” x 47”75 x 120 cm / 29.5” x 47” |

Printablewidth areas | 54 x 118 cm / 21.3” x 46.5” |

Substrate thickness(3) | Min.: 135 gsm and not less than 150 μm / 6 mil before printingand laminationMax.: Up to 600 gsm |

Substratecompatibility(3) | Enhancement on most matte or glossy laminated surfaces, withor without aqueous coating, layered paper, plastic, PVC and othercoated materials. Spot 3D coat directly onto most digital prints. |

UV coatings andcapacity | coating tank for both 2D and 3D applications. One high-capacitytank of 18 liters. “On-the-fly” tank changeover possible duringproduction without any interruption or waste. |

Automaticsheet-fed feeder | High-capacity feeder able to handle a paper pile up to 60 cm /23.6” high for 57 x 120 cm (22.4” x 47”) sheets. Approximately4,000 sheets at 135 gsm. |

Pallet stacker | High-capacity stacker able to accommodate stakes up to 60 cm /23.6” high for 57 x 120 cm (22.4” x 47”) sheets.Approximately 4,000 sheets at 135 gsm. |

Paper path | 100% flat paper pathVacuum feed systemAir feed systemAutomatic double sheet detection |

In-line UV dryer | “On-the-fly” drying and curing via integrated UV lamps |

Front end system | Intuitive touchscreen software management suite controlledby a 27” monitorIncludes functions for operators: Job cost calculator, image editor,queue manager and reprint, camera and printhead settingsDedicated controller for equipment settings and technical dataEthernet connection 10/100/1000 BT in RJ 45 |

iFOIL | Optional Digital Hot Foiling module applicationProduction speed: Up to 1,750 (1) B2 sheets size per hour (or upto 25 m / 65.6’ per minute)Films: Optimization system of film consumptionFilm Rolls: Max. roll diameter and length: ± 30 cm / 11.8”and from 400 – 2,000 m / 1,300’ – 6,500’ of film. Up to threesimultaneous film rolls on the same axis (with a minimum of 10cm / 3.9” per roll). Two cores available: 1” and 3”Maximum surface: Hot foil substrate surface cannot exceed57 x 118 cm (22.4” x 46.5”) (4)Embossing: 3D hot foil raised effects. The surface of the metallizedfilm may be covered with a layer of varnish or another foil |

Other options | Corona (5) (6) substrates treatment module: In-line systemmade to optimize varnish adhesion on complex printedsubstratesPallet feeder: Supports sheets up to size 75 x 120 cm / 29.5” x 47”Pallet stacker: Supports sheets up to size 75 x 120 cm / 29.5” x 47”Variable data printing (VDP)Manage and edit files on the workstationFull variable data (text, graphic, image) for both 2D/3D spotcoating and hot foiling areasIntegrated barcode (1D/2D) reader system and controllerRaster image processor (RIP) as an option |

Maintenance andremote technicalsupport | Daily maintenance completed in less than 10 minutesMajority of procedures are automatedFrom cold start to production in less than 15 minutesRemote troubleshooting and support via included web videocamera (high-speed internet connection required) |

Dimensionsand weightJETvarnish 3D 52L | Up to 12.42 x 1.93 x 1.84 m / 40.7’ x 6.3’ x 6.0’ (L x W x H) (7)Necessary clearance: 1 m / 3.3’ on four sides |

+ iFOIL L | Up to ± 4,529 kg / 9,984 lbs(7) |

Dry air requirements | An on-site dry air system is necessary |

Electricalrequirements | JETvarnish 3D: 400 V, 50/60 Hz, 32A (63A plug)+ iFOIL L: 400 V, 50/60 Hz, 25A (32A plug) |

Operatingenvironment | Temperature: From 18 – 30°C / 64 – 86°FRelative humidity: Between 30 and 50% (no condensation) |