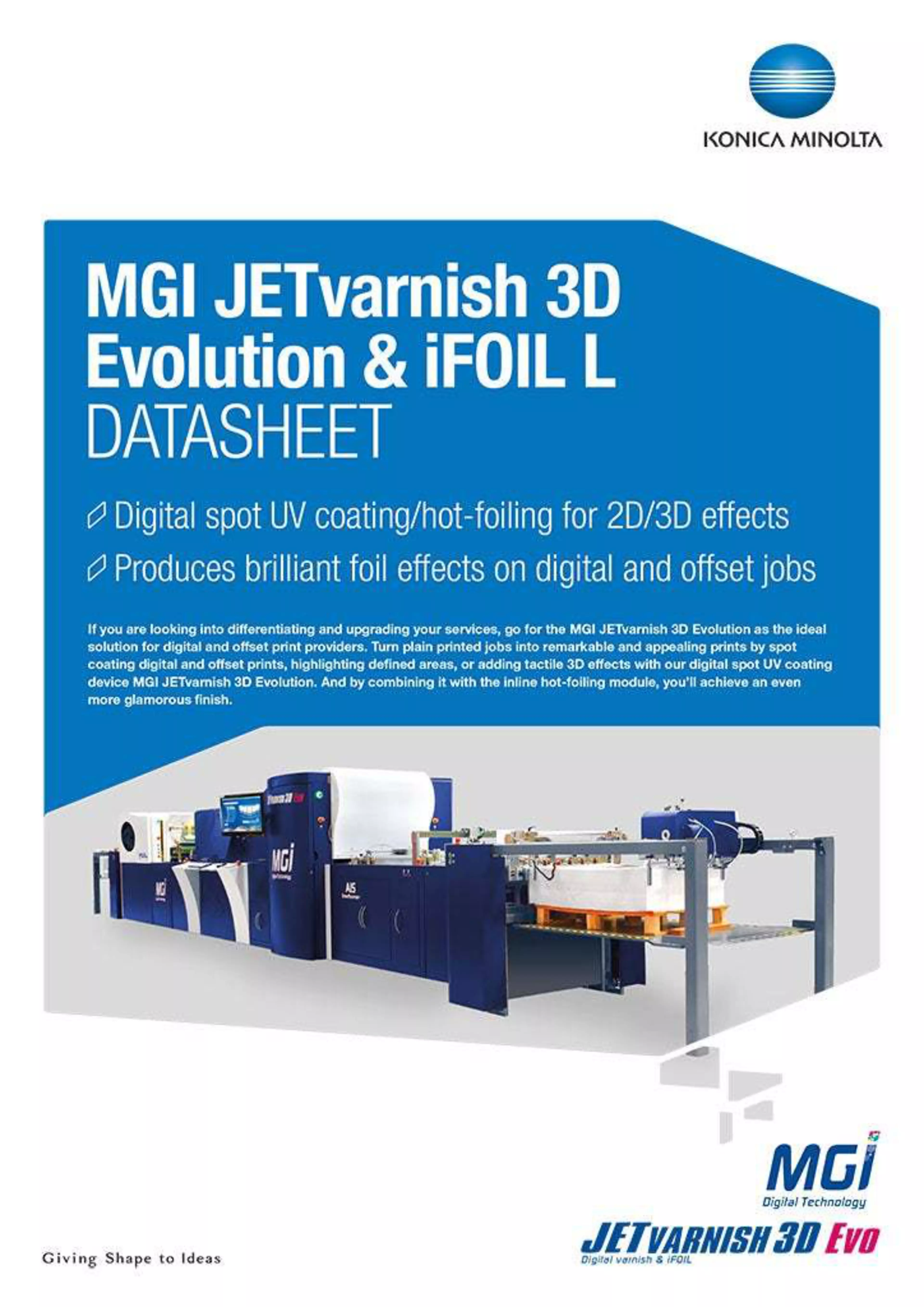

Printing technology | Exclusive MGI inkjet engine technologyDrop-on-Demand (DoD) inkjet applicationPiezoelectric print heads in single pass printing |

Coating thicknesses | Depending on the print file and substrate used, the coatingthickness can vary from a traditional flat spot UV coatingof 3** μm up to 232 μm for 3D raised texture effects and atactile finish. |

Production speed | Up to 3,123 ISO B2 sheets per hour in all versionsThe version Evo 75 can reach up to 4,200* ISO B2 sheets perhour (in landscape) and up to 2,291 ISO B1 sheets per hour |

Registration | SmartScanner coupled with Artificial Intelligence (AIS) for areal-time fully automated sheet-to-sheet registration processNo crop marks required |

Formats | Min: 42 x 29.7 cmMax: 52 x 120 cm 75 x 120 cm |

Printable areas | Max: 51 cm / 74 cm |

Substrate thickness | Min: 135 gsm and not less than 150 μm beforeprinting & laminationMax: 800 gsm and not more than 800 μm beforeprinting & lamination *** |

Substrates | Enhancement on most** matte or glossy laminated surfaces,with or without aqueous coating, layered paper, plastic,PVC and other coated materials. The used substrate needsto be either coated or laminated. Otherwise the media willabsorb the varnish and the desired effect might be lost |

Varnish on toner | Spot 3D coat directly onto most** digital prints |

UV coatings and capacity | 1 coating tank for both 2D & 3D applicationsOne high capacity tank of 18 litres“On-the-fly” tank changeover possible during productionwithout any interruption and no waste |

Automatic feeder | High capacity feeder for paper stacks of up to 60 cm heightfor 75 x 120 cm sheets ***Approximately 4,000 sheets at 135 gsm |

Pallet stacker | Supports sheets of up to 75 x 120 cm size on pallet packaging |

Paper path | 100% flat paper pathVacuum feed systemAir feed systemAutomatic double sheet detection |

Front end system | Intuitive touchscreen software management suite controlledby a 27’’ monitorJob cost calculator, image editor, queue manager and reprint,camera and print head settings and reprint, dedicatedcontroller for equipment settings and technical dataEthernet connection 10/100/1000 BT in RJ 45 |

In-line UV dryer | “On-the-fly” drying & curing via integrated UV lamps |

Maintenance & remote technical support | Automated inkjet head cleaning and wipingDaily maintenance completed in less than 10 minMainly automated proceduresFrom cold start to production in less than 15 minRemote troubleshooting & support via included web videocamera (high-speed internet connection required) |

Operator panel | Integrated user-friendly LCD touchscreen |

Production speed | Up to 2,300 B2 landscape sheets per hour |

Formats | Up to 75 x 120 cm |

Hot foil stamping area | Max: 74 x 119 cm |

Substrate thickness | Min: 150 μmMax: 600 μm (standard), 800 μm (optional) |

Foil rolls | Max. roll diameter and length: approx. 30 cm and from400 to 2,000 meters of filmUp to 5 simultaneous film rolls on the same axis(with a minimum of 10 cm per roll)2 cores available Change for: 1 inch as standard and3 inches as option |

Dry air | Requires air without oil at 6 bar (87 psi) & 24 m3/h (14 cfm) |

Dimensions (L x W x H) | Up to 12.72 x 1.86 x 1.84 meter (Evo 75 full options) |

Weight | Approx. 4,524 kg |

Electrical requirements | 40 kW (63 A) at 400 Volts - 50/60 Hz + 20 kW (32 A) at400 Volts - 50/60 Hz |

Temperature | 18 to 30°C |

Relative humidity | between 30 and 50% (no condensation) |

Corona1/2 substratestreatment module | In-line system to optimise varnish adhesion on complexprinted substrates |

Variable Data Printing(VDP) | – Full variable data (text, graphic, image) for both2D/3D spot coating and hot foiling areas– Integrated barcode (1D/2D) reader system & controller– Raster Image Processor (RIP) as an option |

| Not Available |

| Not Available |