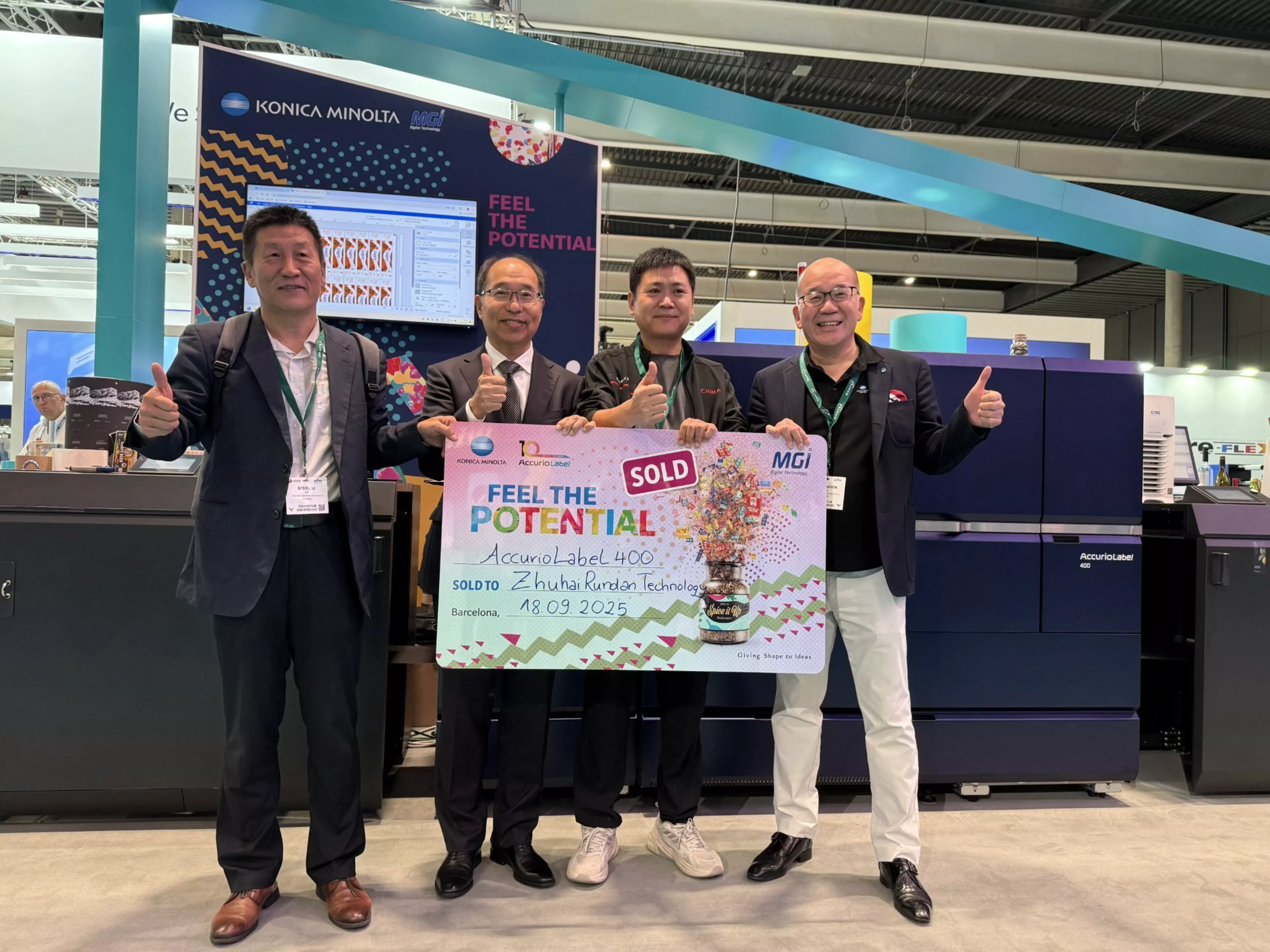

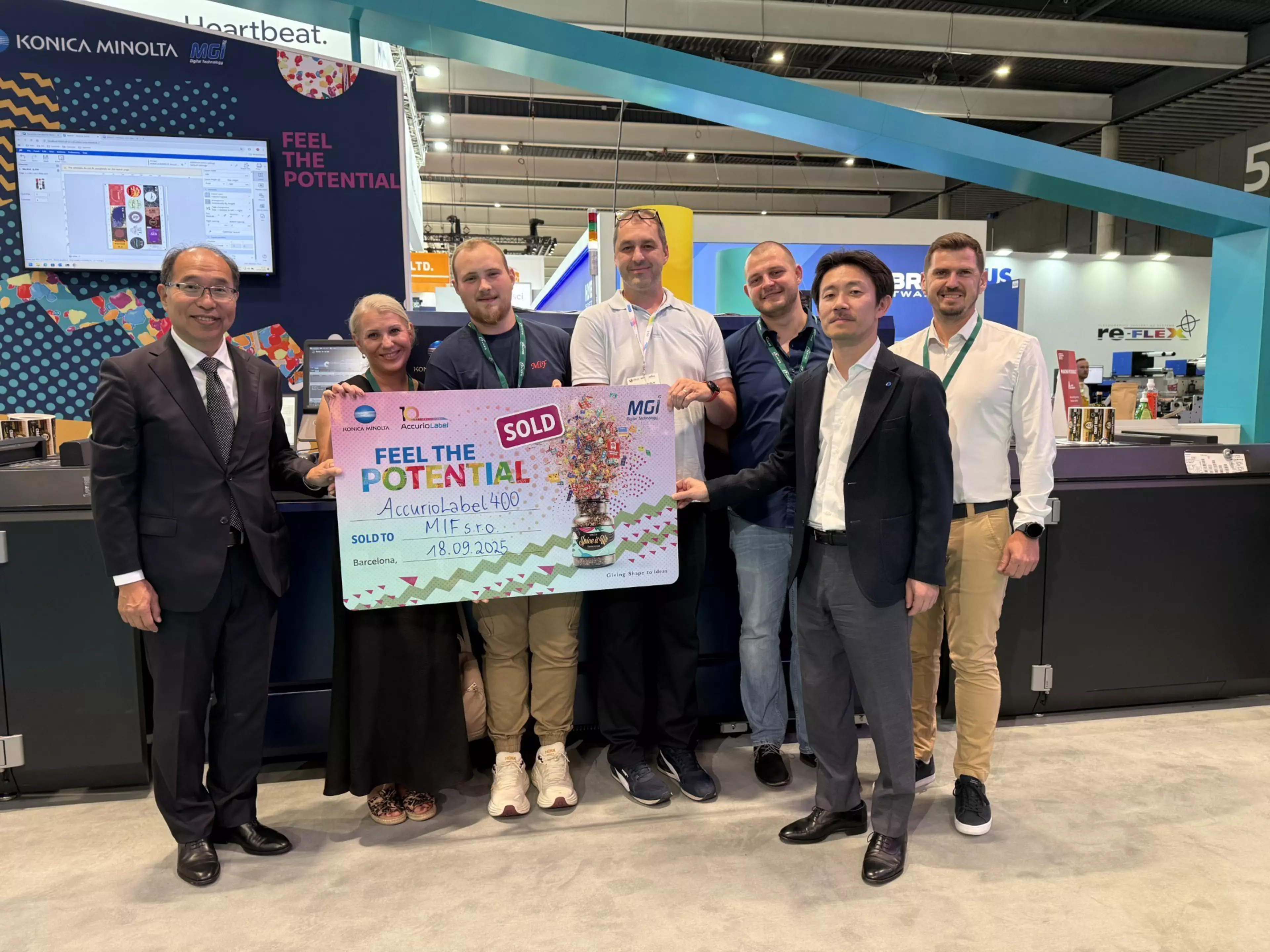

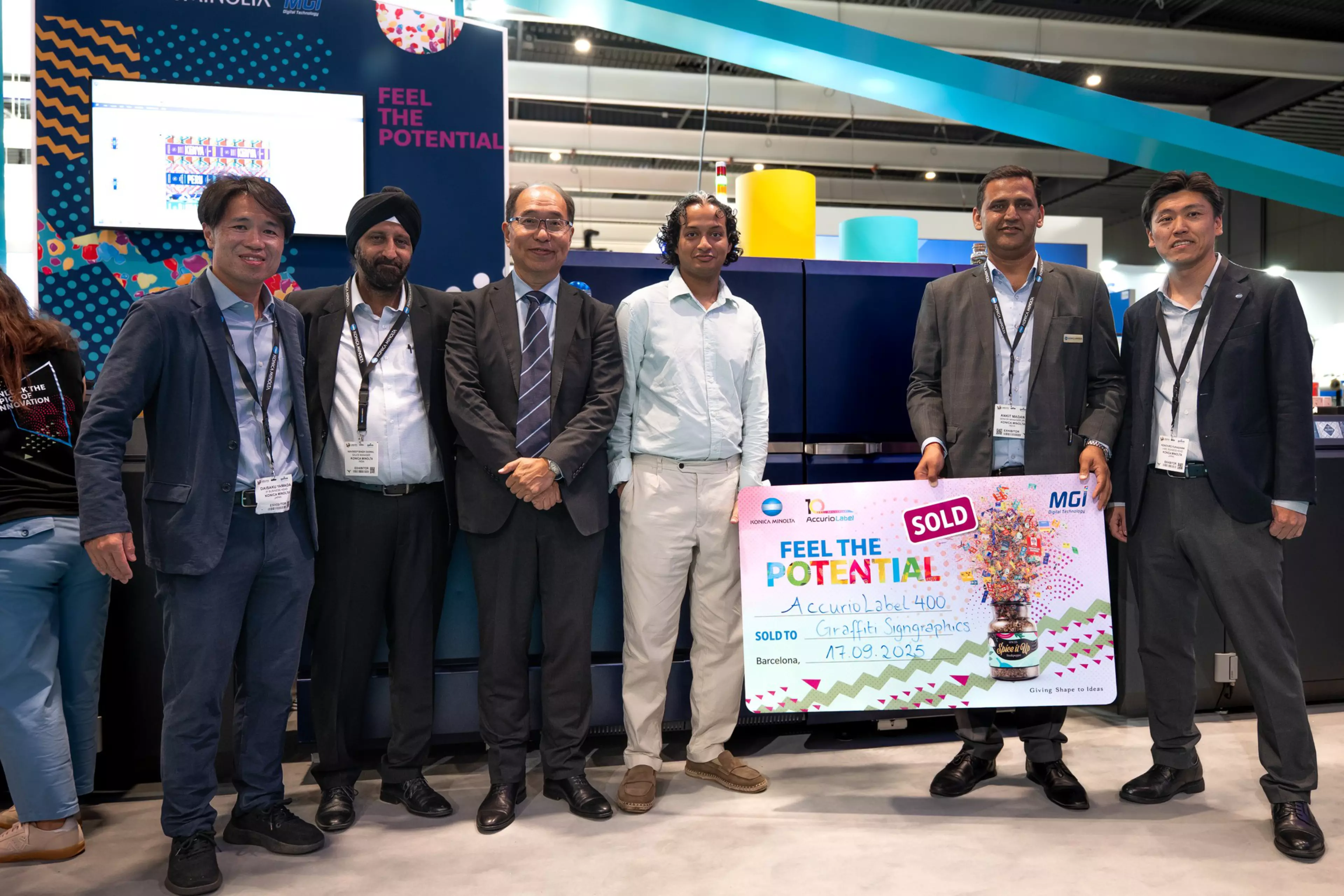

Konica Minolta, European market leader in digital label press systems, is celebrating its 10th year of label expertise with unparalleled success at Labelexpo following a near 25% increase in sales leads and 15 new show sales.

A standout highlight was the debut of the new Konica Minolta AccurioLabel Prototype. The cutting-edge system is engineered to elevate automation and productivity while tackling key challenges in the label printing industry.

Building on the proven performance of the AccurioLabel 230, the next-generation prototype is tailored for mid-range digital label production. It features an optional Intelligent Quality Optimiser (IQ), which streamlines workflows, supports extended print runs of up to 1,600 linear meters, and maintains precise color registration - even at top speeds of 23.4 m/min. With an upgraded print resolution of 1200 x 2400 dpi, the system delivers exceptionally sharp and vibrant results.

It was presented alongside Konica Minolta’s full portfolio of digital label and packaging workflow solutions developed to help customers unlock hidden potential and showcased in partnership with MGI Digital Technology.

This included the AccurioLabel 230 (CMYK) for providers transitioning volumes from conventional to digital, the AccurioLabel 400 (CMYK + White), and MGI’s JETvarnish 3D Web 400 for digital embellishment. Also featured was the MGI Octopus Web for hybrid digital cutting and finishing, and the GM DC350Mini Basic for semi-rotary die-cutting and lamination.

Demonstrations of the AccurioPro Flux, AccurioPro Dashboard, and the IC-320L Creo controller, complemented by MGI’s Connect (Dashboard, Approve, Predict) and THE JETFORCE platforms.

Toshi Uemura, Head of Industrial Print at Konica Minolta Europe, said: “In the year that marks a decade since Konica Minolta entered the label market, we were excited to showcase what is next as we help today’s highly pressurised production environments address demands on productivity. We also wanted to demonstrate how we deliver technology excellence that manages shorter lead times, smaller job volumes, a shortage of skilled operators and environmental concerns.