What is SmartFactory?

SmartFactory by Konica Minolta combines intelligent technologies to help factories and production teams work more efficiently. It connects smart robots, AI-based visual inspection, and automated transport systems into one flexible, easy-to-use solution.

Whether you're improving product quality, reducing manual tasks, or scaling operations, SmartFactory is here to help you do it better and with less effort.

Why it Matters

Many companies still depend on repetitive work that takes time, costs money, and often leads to mistakes. SmartFactory replaces that routine with smart tools that work 24/7, fit into your existing systems, and free up your team to focus on what really matters.

It’s not about replacing people, it’s about giving them better tools to succeed.

FORXAI Mirror

Smart monitoring for safer workplaces

Secures access to hazardous production areas and reduces the risk of contamination.

Ensures employees enter production with the protective equipment required by the company.

Ensures the proper usage of the protective equipment.

In case of an accident, it provides statistics and reports with precise date and time.

Advanced Automation Solutions

Smarter tools for inspection and logistics

This is where robots and software work together to handle the repetitive stuff, like checking product surfaces or moving materials across your site.

From visual quality inspection with cobots to fully autonomous material handling, these solutions are made to plug into your workflow, scale with your needs, and free up your people to focus on higher-value tasks.

Whether you’re in automotive, electronics, pharma, or logistics, this is your gateway to faster, safer, and more reliable manufacturing.

Quality Control

Quality control helps with Increasing Efficiency and Reducing Delays

Quality control in manufacturing, logistics, warehouse, and similar environments is a critical but expensive and time-consuming process. In a complex or high-speed environment, human inspectors may struggle to keep pace or become distracted or fatigued, potentially leading to missing defects, anomalies, and other issues.

Our visual inspection systems use high-resolution cameras and Artificial intelligence to detect defects directly on the production line. From scratches and dents to color shifts and surface inconsistencies, the system spots even the smallest issues in real time, without slowing down your process!

FORXAI Mirror

FORXAI Mirror is an advanced AI-driven device that visually confirms whether employees are wearing the correct protective equipment before entering sensitive production zones. With high-resolution cameras and intelligent analysis, it automatically verifies PPE compliance in real-time and seamlessly connects to access control systems. It supports traceability with incident reports and equipment usage insights, helping companies reduce risks, optimize safety investments, and meet strict EU regulations.

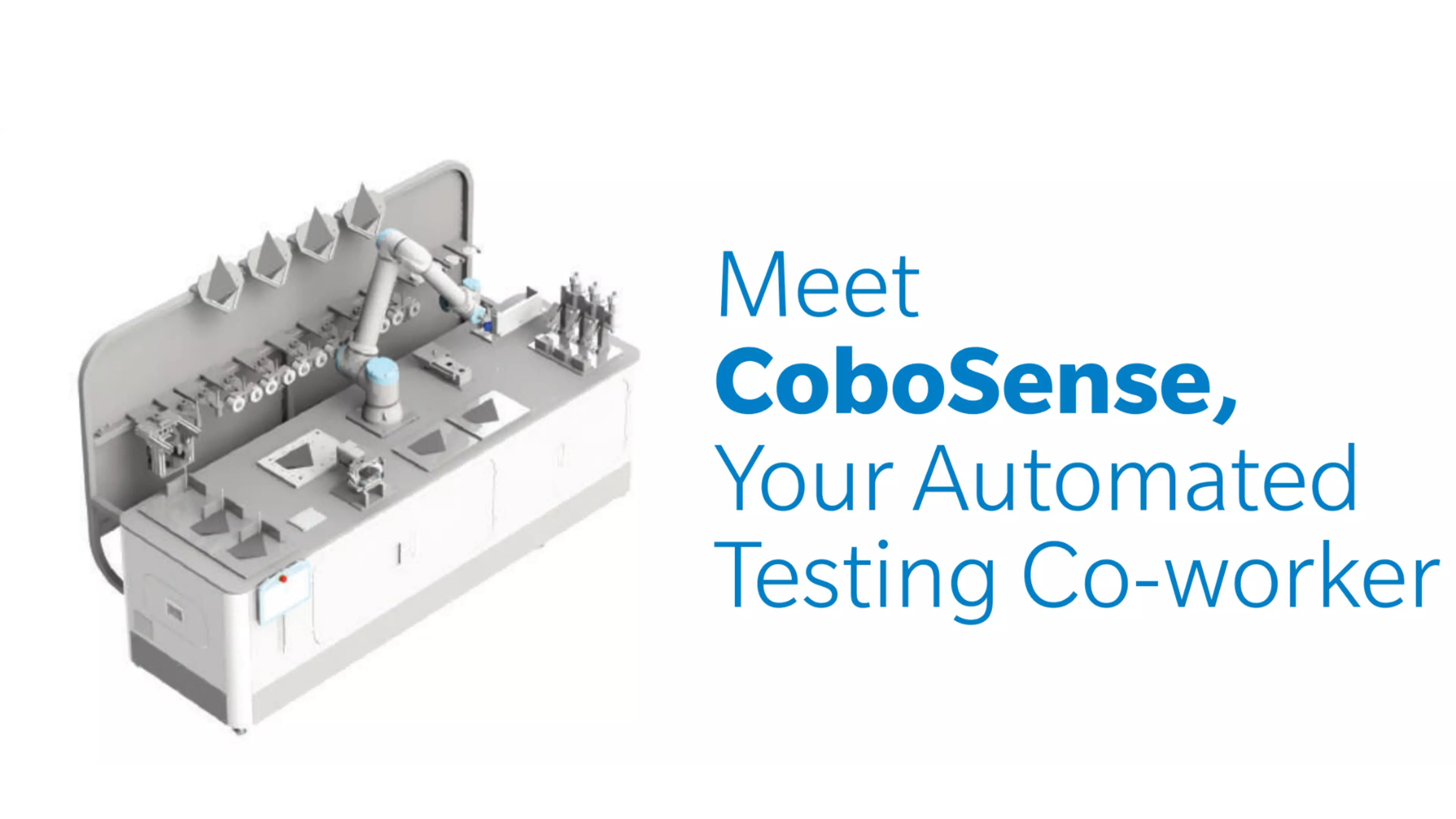

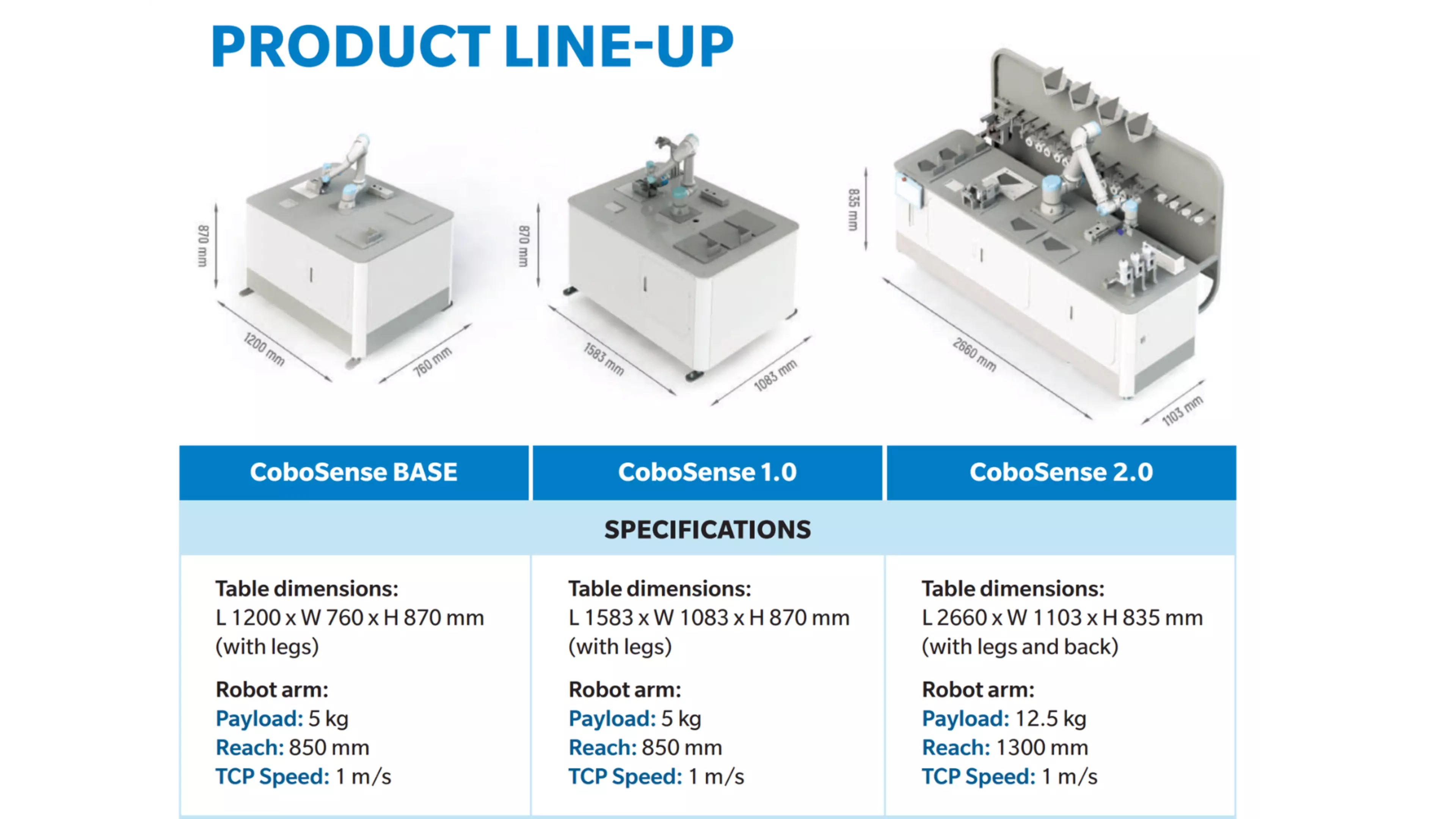

Advanced Automation Solutions

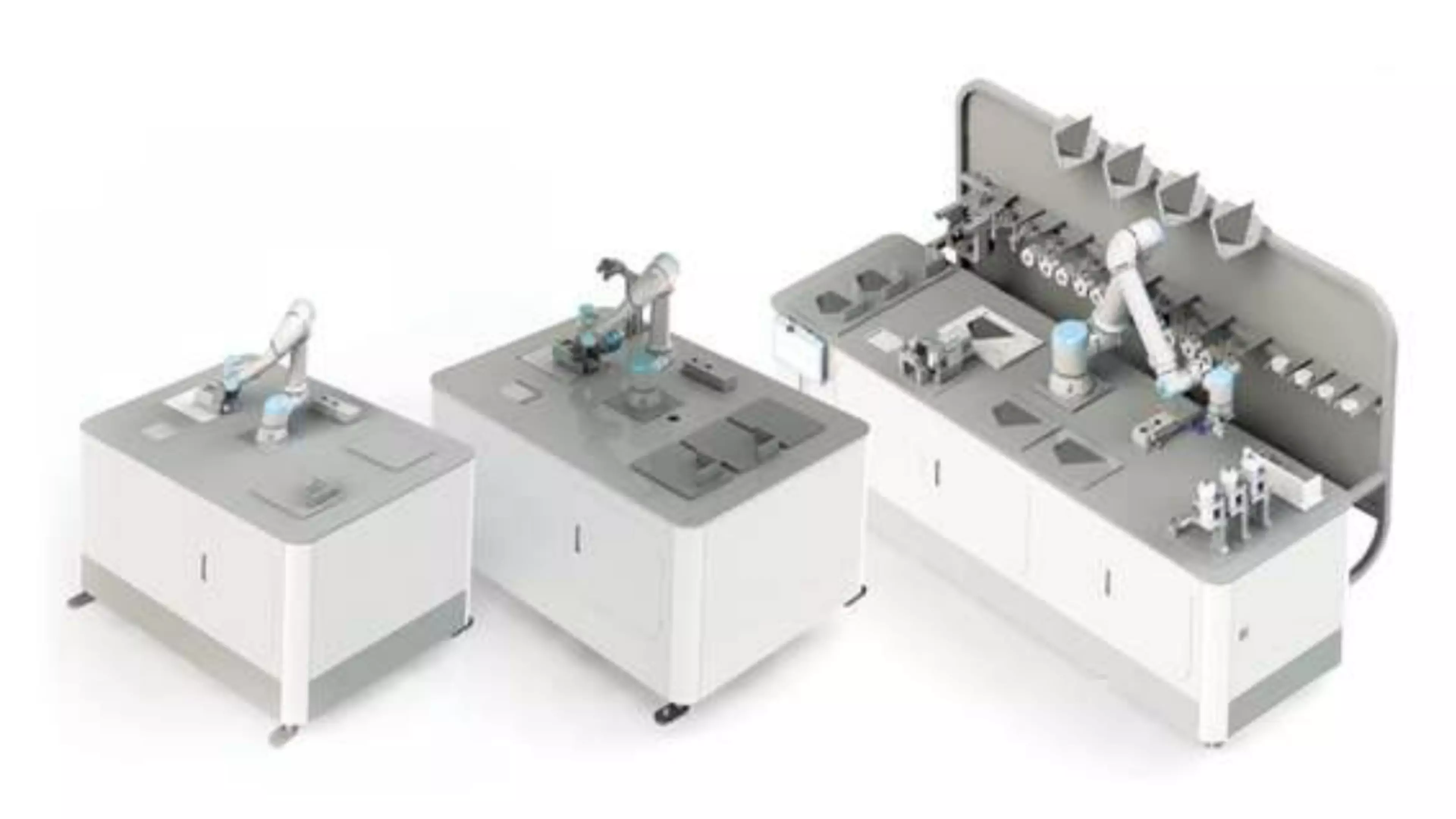

Flexible robotics and smart systems that fit your production

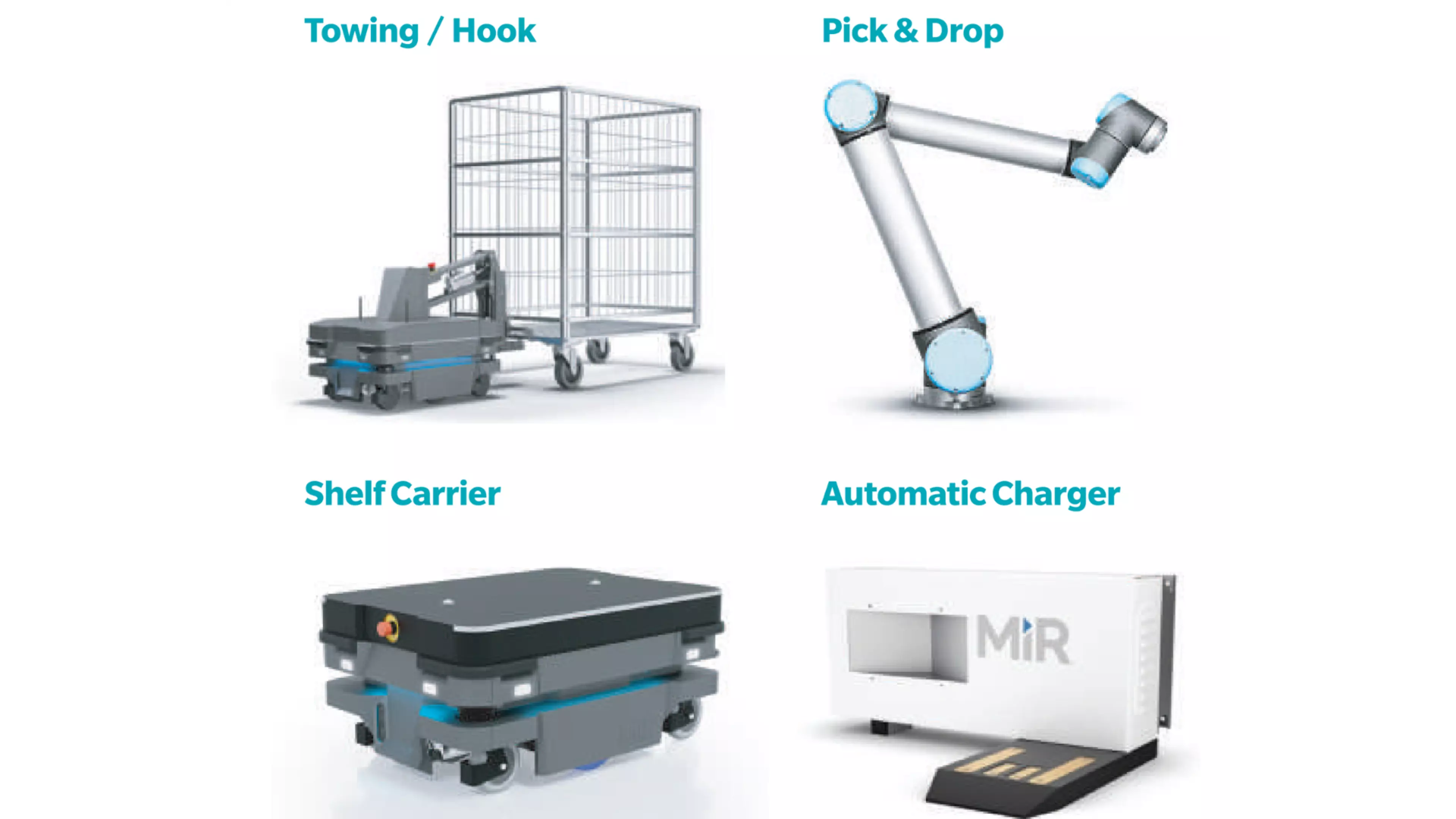

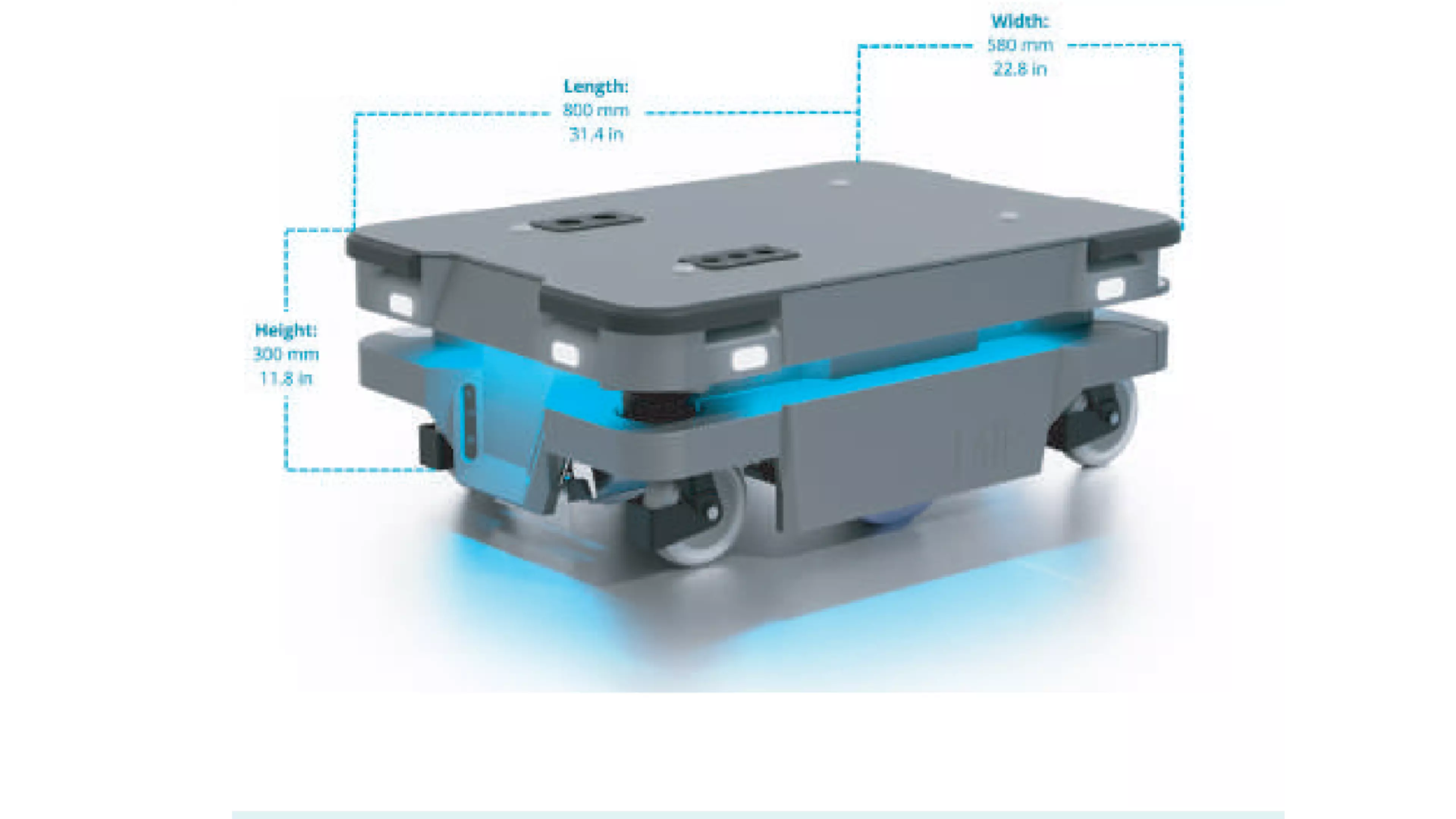

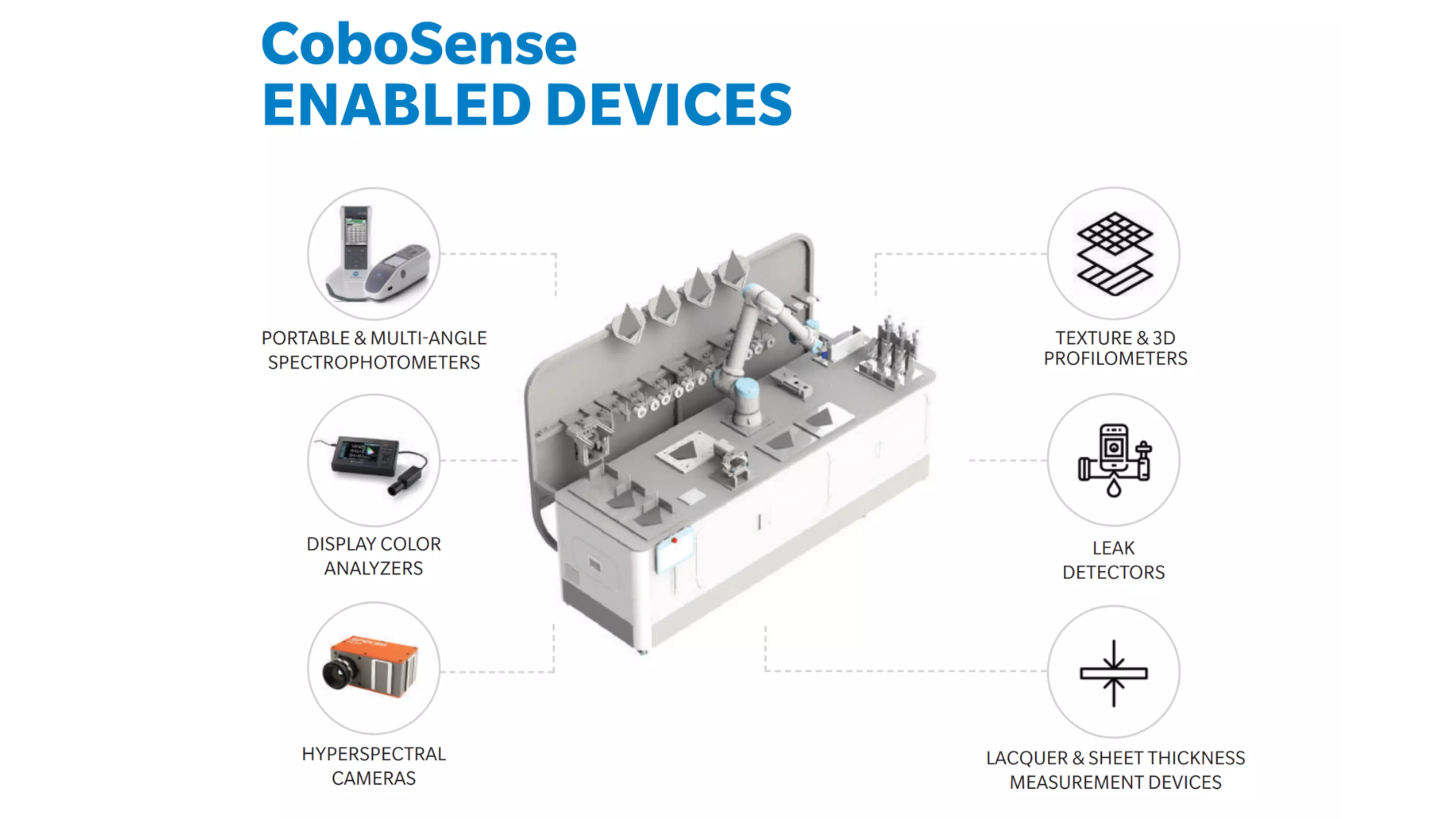

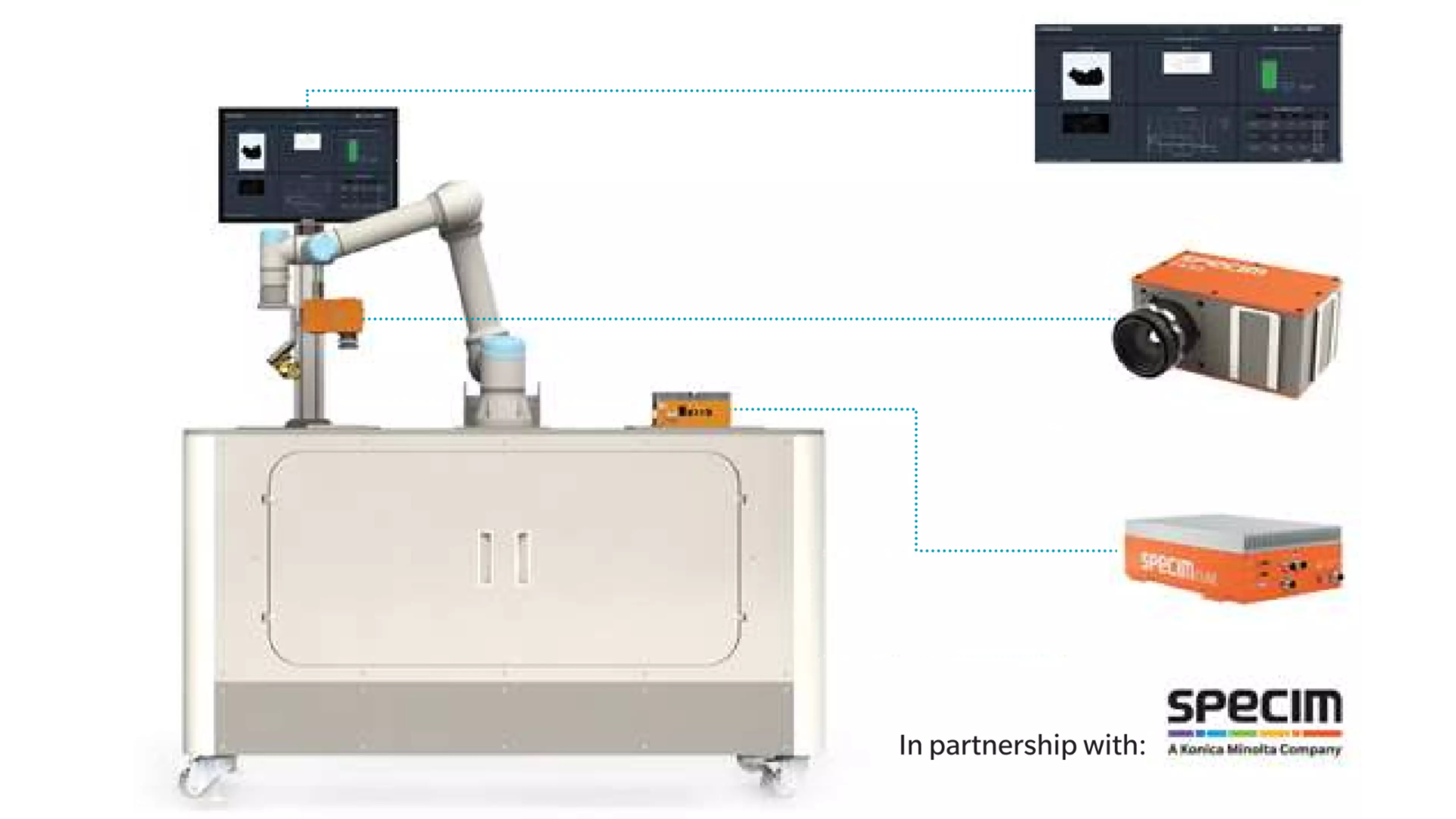

Our Advanced Automation Solutions bring together collaborative robots (cobots), machine vision, and autonomous mobile robots (AMRs) to streamline your factory’s most repetitive and time-consuming tasks.

From precise surface inspection to fully automated material transport, these systems are designed to boost productivity, reduce errors, and integrate smoothly with your existing operations.

FORXAI Mirror showcase

Seamless Access Control Integration

Quick and Easy Employee Check

Showcase of the Advanced Automation Solutions