Identify and fix assembly issues, enhance quality control

Ensuring products are correctly assembled — whether on an automated production line or in a manual manufacturing process — is critical to maintaining a manufacturer's reputation and keeping customers satisfied and safe. No consumer wants their new product to fall apart, stop working or cause an accident owing to missing, defective or badly fitted components.

Correct assembly will also be a requirement for workplace health and safety. A warehouse or factory that moves heavy loads or products in and out of storage or along a production line must ensure they're correctly positioned on, or firmly attached to, the transport mechanism. Otherwise, tipping, swaying or falling items could put workers in danger, or damage other goods and equipment.

If you rely on people to perform assembly quality checks, you may run the risk of errors being missed — as humans inevitably get tired or distracted; or don't have enough time to inspect every item. With an inspection solution based on video analytics, however, you can:

- Automate and enhance the assembly quality control and inspection process

- Increase your confidence in quality assurance and in issues being spotted

- Have the opportunity to resolve issues before they turn into problems that could affect your reputation, your customers, your workplace or your people

Customer benefits

Konica Minolta's

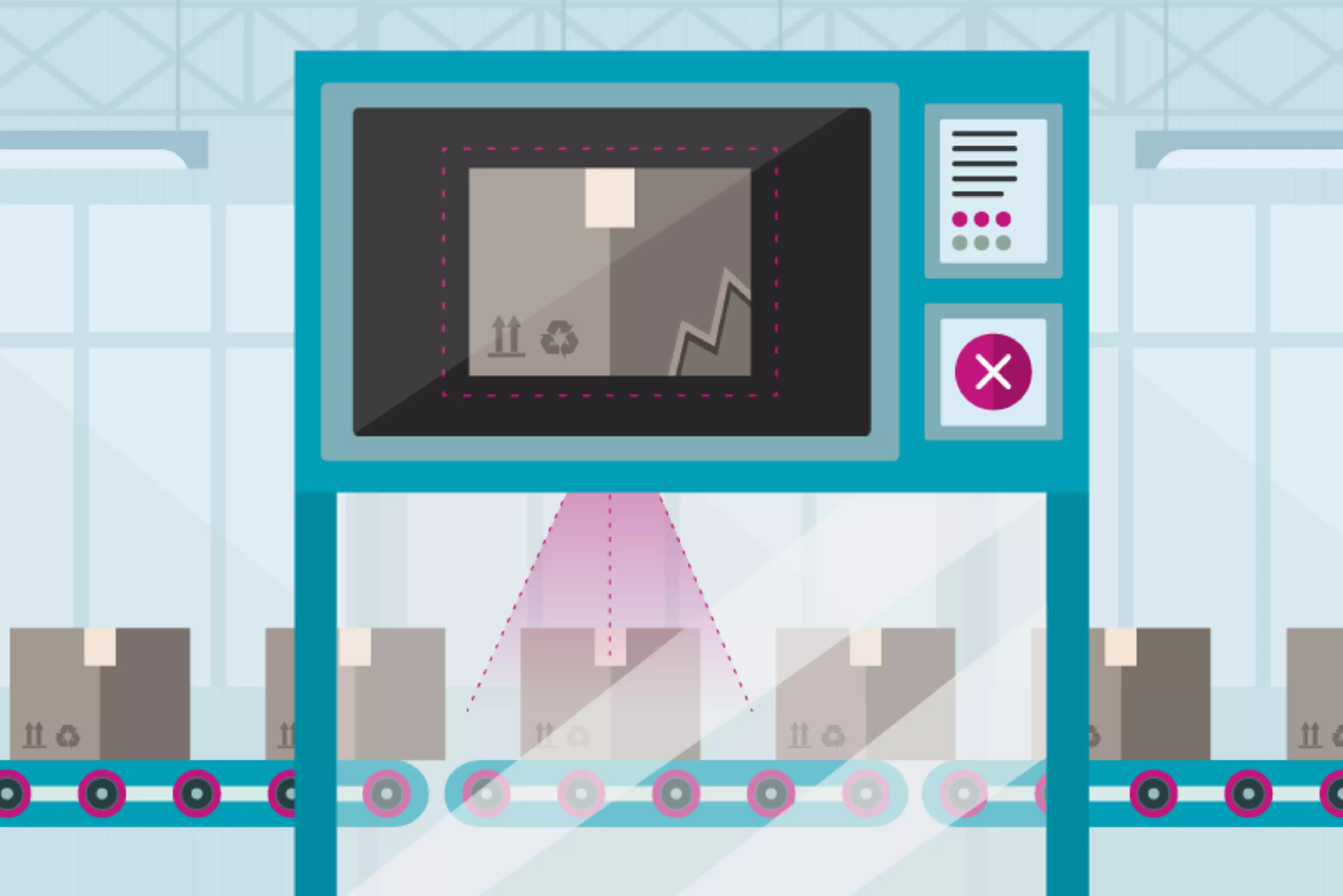

Video Quality Inspection (VQI) solutions are helping companies improve their assembly quality inspection processes. Our

VQI solutions combine our smart IoT-based Mobotix video cameras with FORXAI, our imaging IoT platform. FORXAI enables immediate AI-based processing of camera images and video — on site or in the cloud — to screen, monitor, measure and analyse against pre-defined thresholds or other criteria.

Among our customers are a white goods manufacturing company that uses our

VQI solution to help ensure it delivers appliances that customers can rely on. Our solution checks that all component bolts are in place before the appliance's top cover is mounted; and verifies the quality and readability of the barcode on each appliance.

At the other end of the scale, an automotive manufacturer prevents workplace injuries and other dangerous situations by using a

VQI solution to ensure semitrailers are correctly attached to crane heads before being moved.

Detect and alert to anomalies and errors

Increase inspection consistency compared with human inspectors

Improve process efficiency

Help raise the quality of goods delivered to customers

Help reduce risk in manufacturing and other industrial environments

Assembly Quality Inspection: Monitoring of missing or incorrect manufacturing components

Assembly Quality Inspection from Konica Minolta monitors any missing or incorrect bolts, screws, flanges, or any other essential manufacturing components on an assembly production line. It is an in-house developed solution based on FORXAI, Konica Minolta’s image IoT platform that accelerates the digital transformation of society together with customers and partners.

Why Konica Minolta for Video Solution Service – Making the invisible visible

Konica Minoltas intelligent video system can solve problems in all areas: Ensuring safety in a factory unit, registering vehicles to detecting movement, communicating with the network or triggering alarms if necessary. The solution also allows you to analyse the customer behaviour.