What It's About

Advanced Automation Solutions from Konica Minolta help you do more with less. We combine smart robots, powerful software, and proven workflows to handle the heavy lifting, both literally and digitally. From visual inspection to material handling, our systems are designed to fit into your factory without any big changes.

Why It Matters

Many factories still rely on repetitive manual work that takes time, costs money, and often leads to mistakes. With our solutions, you can automate those tasks while keeping control and improving quality. These systems are modular, safe to work alongside people, and easy to adapt as your needs change.

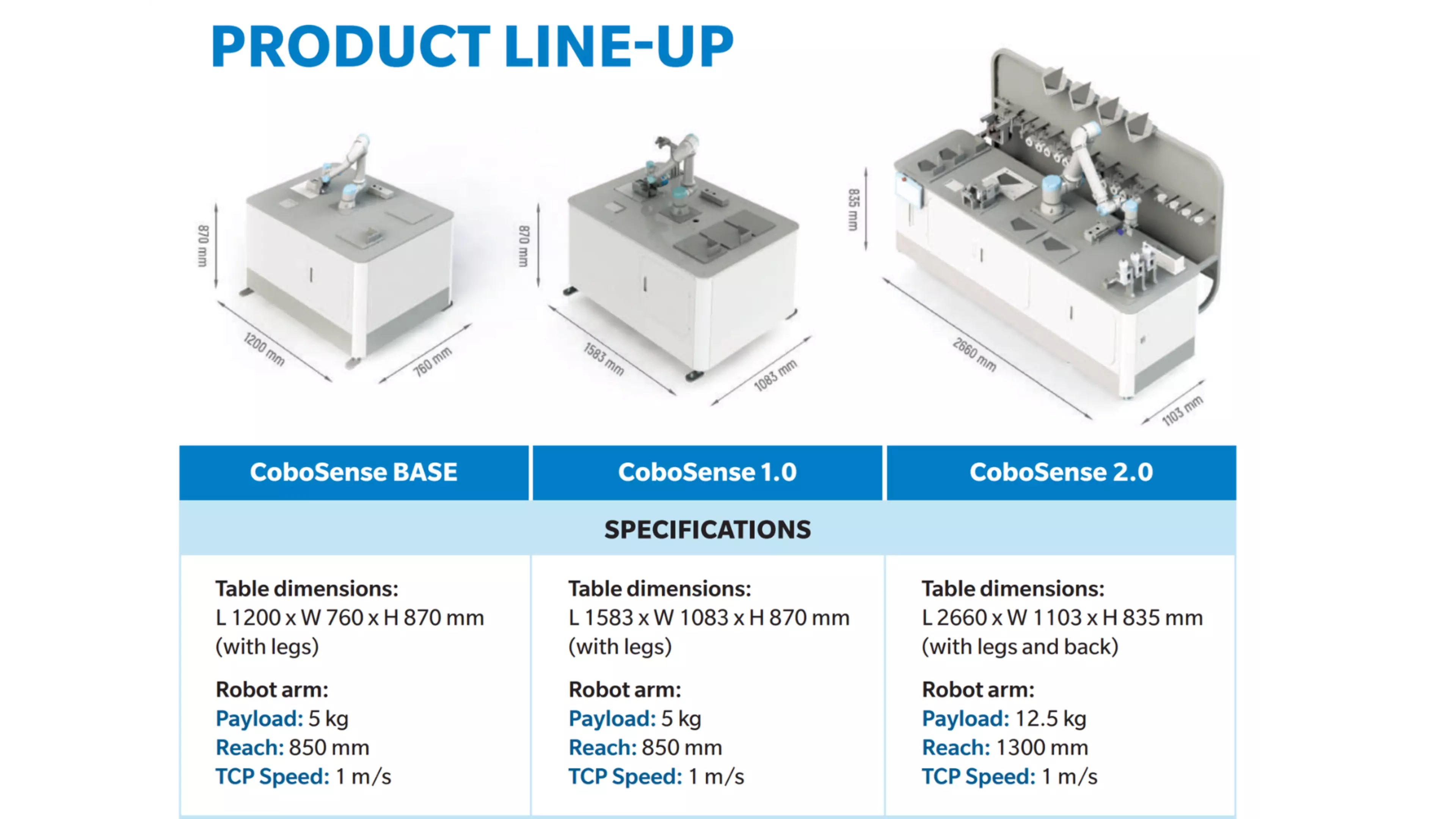

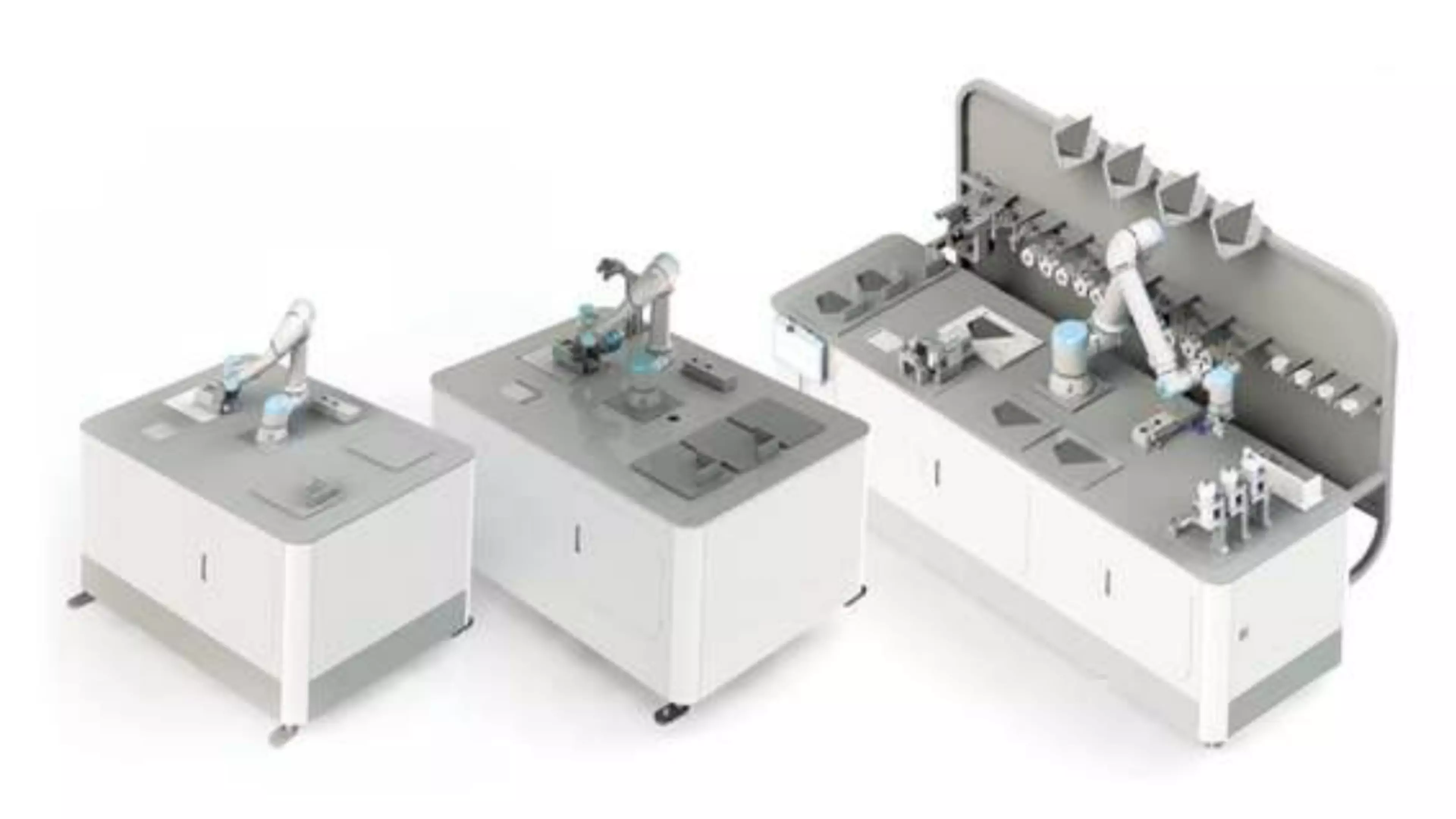

🦾 CoboSense

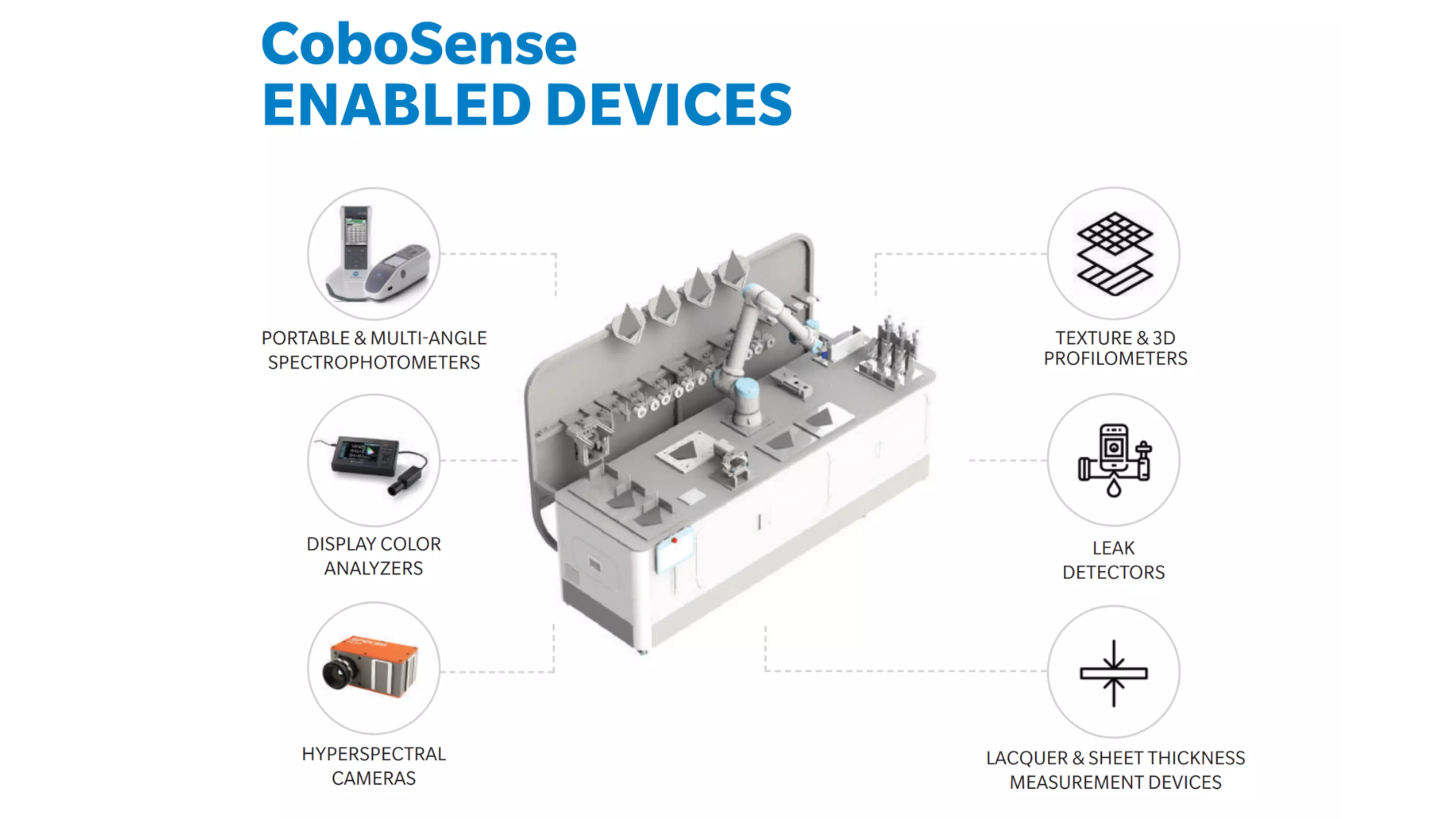

- Handles scratches, marks, abrasions, and surface testing

- Works with plug-and-play modules and sensor tools

- No-code setup — just guide the robot arm manually

- Batch testing with automated reporting

- Runs 24/7 with little supervision

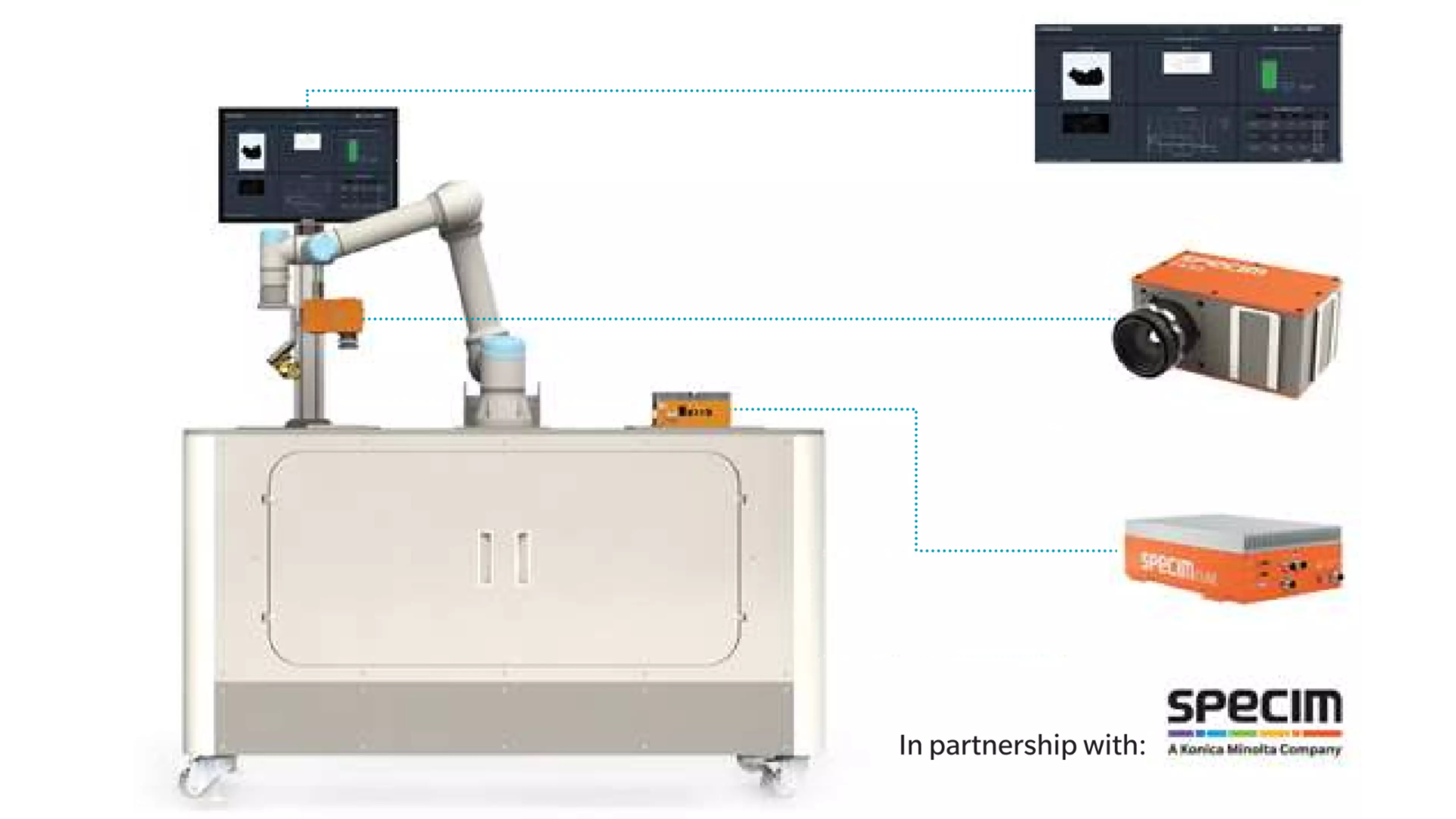

🌈 CoboSpecim

- Uses hyperspectral imaging to “see” beyond human vision

- Detects material differences, defects, or inconsistencies

- Runs real-time analysis with SpecimCUBE software

- Perfect for paints, plastics, coatings, and more

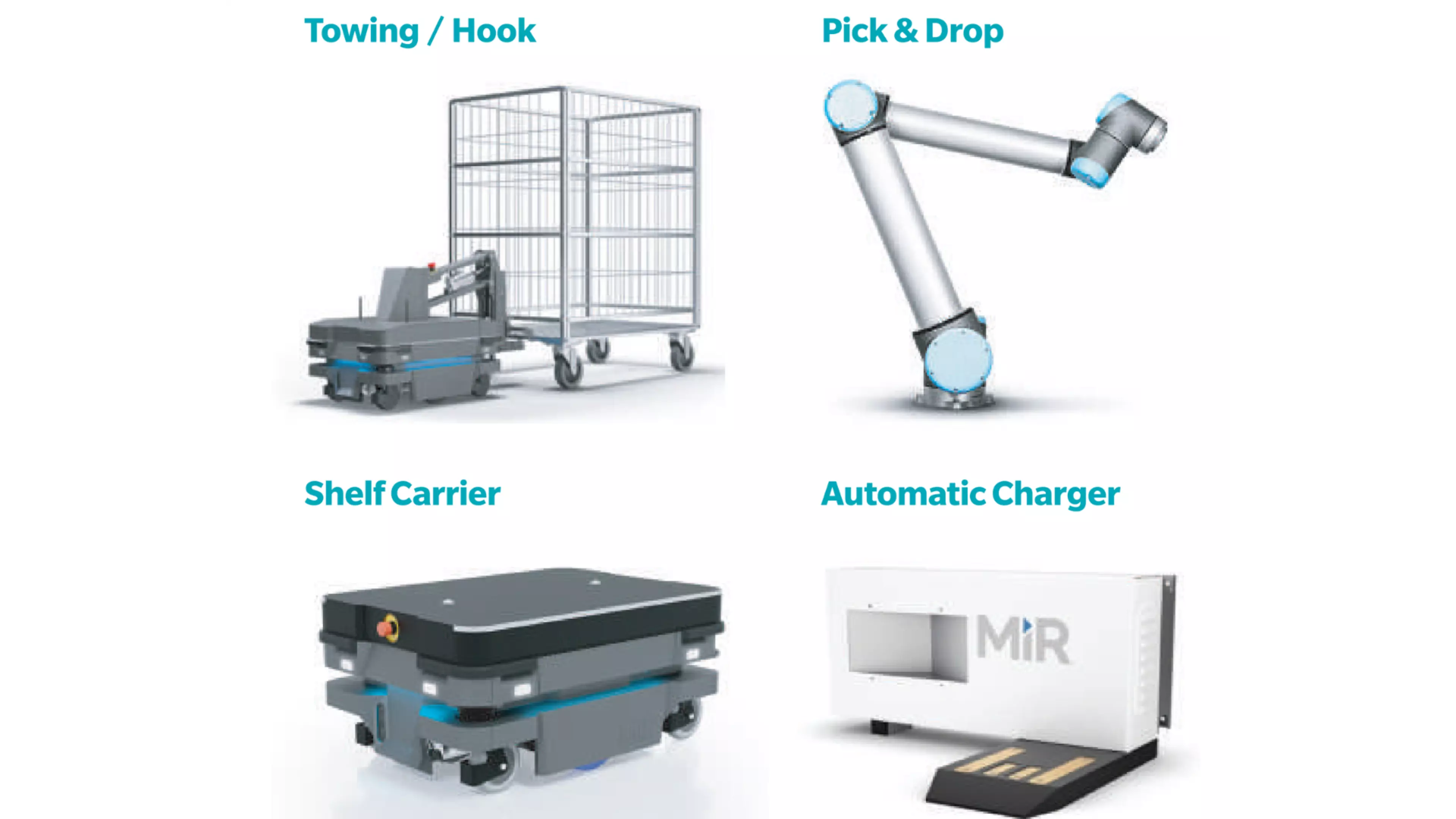

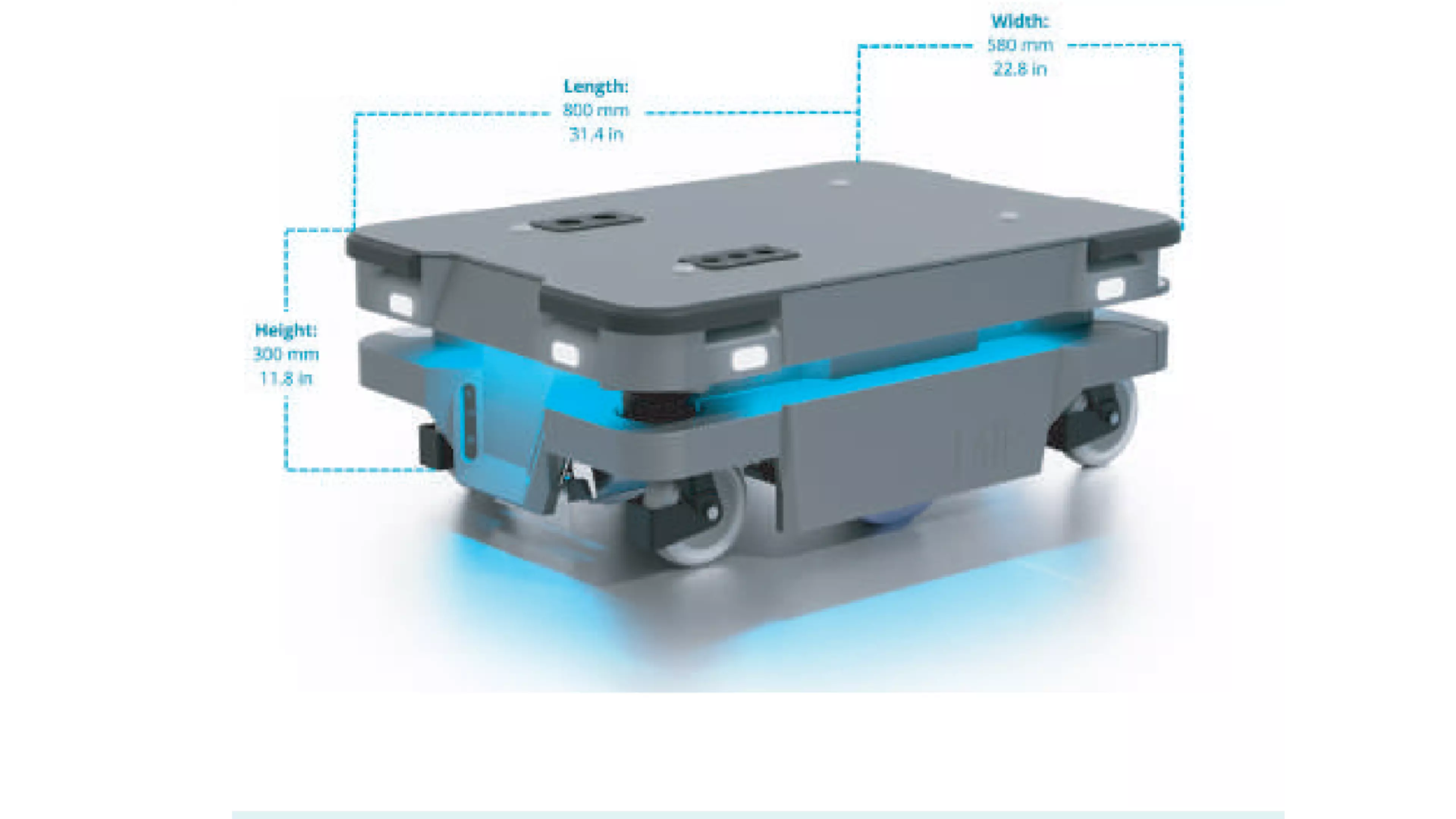

🚚 Autonomous Material Handling (AMH)

- Mobile robots (AMRs) that transport goods on their own

- Integrated software for traffic control, analytics, and workflow

- Connects with lifts, doors, sensors, and ERP/MES systems

- Reduces manual labor and safety risks

- Scalable to grow with your production needs

Repetitive surface testing eats up time and slows your team down. CoboSense takes over these tasks and runs them consistently, around the clock.

🧪 Runs up to 10+ different test procedures

👆 Works by simply guiding the robot arm, no programming required

📋 Automatically creates digital reports while you sleep

🛠️ Modular setup fits different sample sizes and tools

It’s already helping large-scale manufacturers, including one of the world’s biggest car plants, to test faster, save money, and make better use of skilled workers.

Even the best human eye can’t spot everything. CoboSpecim uses hyperspectral imaging to inspect materials in ways traditional cameras can’t.

🔬 Sees through coatings or material layers for hidden issues

📈 Digitizes every result for easy reporting and traceability

♻️ Helps reduce waste by catching defects early

🧠 Works well in automated or hybrid testing lines

From packaging to paint, plastics to food-grade materials, CoboSpecim brings a new level of insight to your quality control.

Moving materials across your factory takes time, effort, and coordination. Our Autonomous Mobile Robots (AMRs)

From raw materials to finished products, AMRs move whatever you need.

📦 Transports goods between workstations, shelves, and docks

🧠 Uses smart mapping, 360° vision, and obstacle avoidance

⚙️ Connects to lifts, automated doors, and sensors

🔄 Adjusts routes in real time based on traffic and job status

🔌 Charges automatically when idle