Tactile prints and metalized surfaces evoke emotions, create an immediate emotional response, and help your customers sell better. Read here how the eye-catching finishing techniques work and how to get customers excited about them. This is how you attract attention and hands to your print products instead of being lost in the flood of online information.

A hat with a veil of black lace adorns a book cover. The delicate lace ornaments shine sublimely on the matt background and look as if they have been cut out - the first impulse: customers want to touch the book to feel and touch the structure. A sensual experience that generates emotions and even the desire to buy the book. Joann Peck and Jennifer Wiggins have investigated this connection. In a study on tactile sensations, the US marketing professors show that product packaging that feels interesting can increase sales.

Sales growth is a goal that both printers and brand owners always have in mind, along with customer satisfaction. Currently, younger marketers are prioritizing online processes and digital content. This is legitimate, because powerful algorithms track customer reactions, automatically start interactions and measure whether goals have been achieved. But beyond these digital processes, it is important to remember that people are sensitive beings who want to flip through catalogues and touch brochure covers. Studies show that the longer people spend with a product, the more interested they are in buying it. So, if you want to stand out from the crowd and achieve extraordinary sensory reactions among your clientele, you should try to print packaging, book covers or even customer mailings for selected occasions with tactile special effects.

The way out of the niche

In terms of printing, the tactile special effects such as spot gloss, three-dimensional printing and visual metallic, glossy looks have been possible for some time. However, they were reserved for the premium segment for a long time. With the conventional production methods, extravagant finishes could often be inefficient and time-consuming, so that they were out of the question as a service, especially for short runs with tight deadlines. With the new 3DJetvarnish digital technology from the French company MGI, Konica Minolta is now revolutionizing the industry for print service providers who want to offer brand owners particularly creative and eye-catching solutions. The result is a completely new, haptic experience that stands out from the crowd of ordinary printed products at first glance. Simultaneously, the technology allows to individualize embellished print products to the same extend as digital content. Thus, personalized packages or brochures catch the customer`s attention and maximise response.

Tactile and ecofriendly metal effects

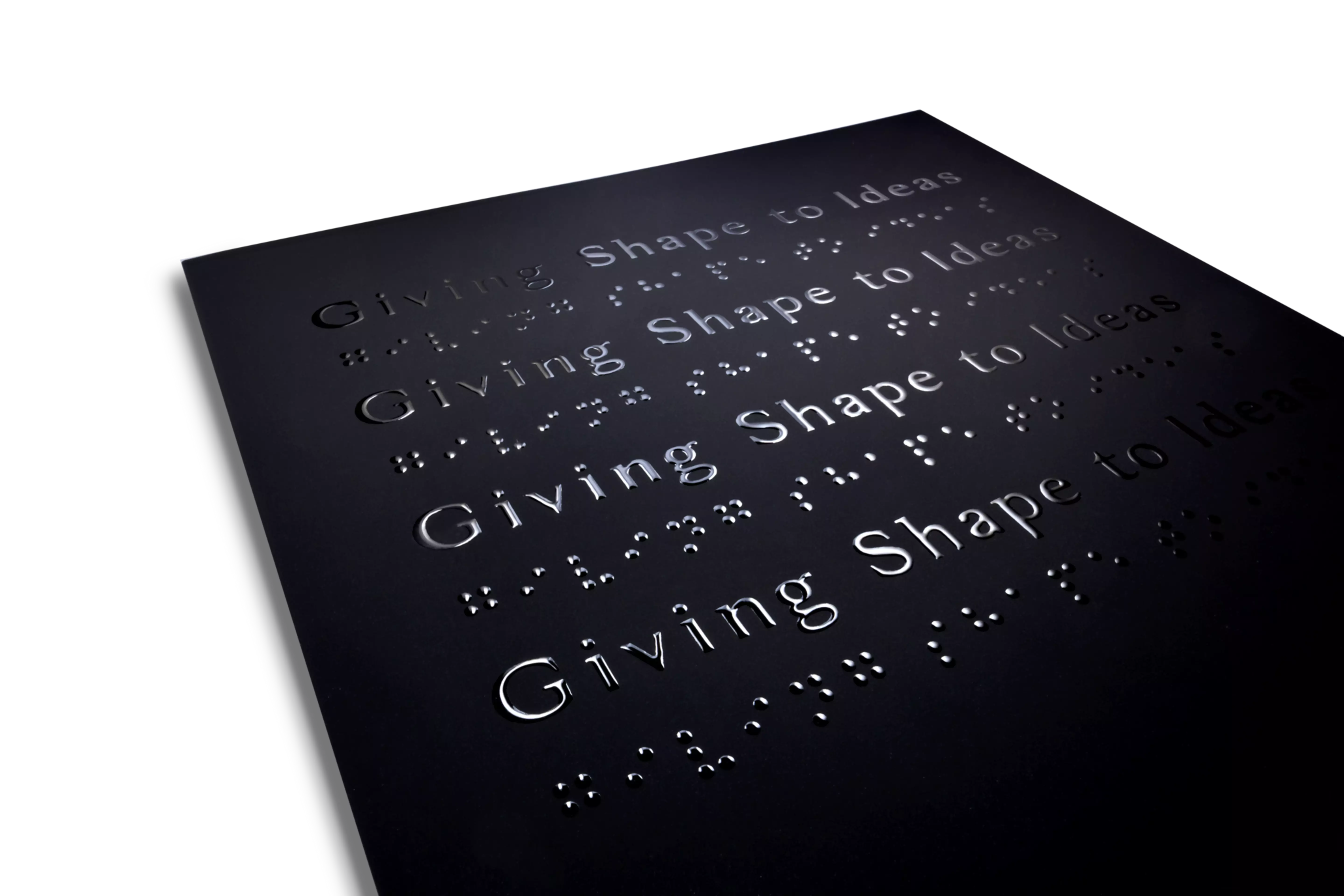

The new technology prints with precise spot varnishing, highlights specific areas and adds 2D or 3D effects. The secret is to prepare the substrates well for varnishing or hot wrapping. The so-called corona pre-treatment is suitable for this. It creates a functional layer on foils, for example, which ensures optimum wetting behavior and sufficiently good ink anchorage. Depending on the design, UV coating pigments are selectively applied in layers. The more layers of varnish are applied, the easier it is to feel the motif. For Braille, for example, the highest possible number of printable layers is achieved.

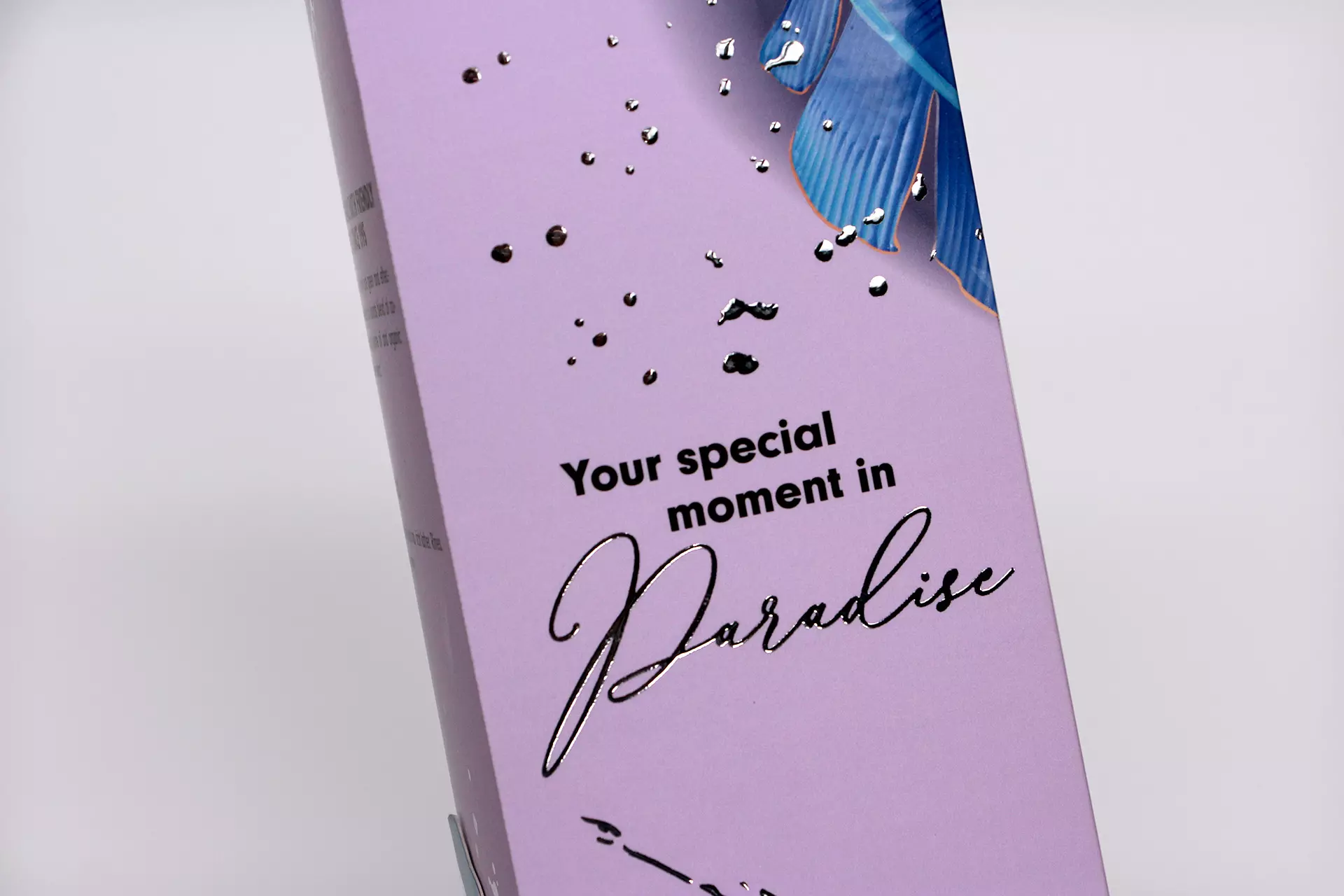

Additional response can be achieved with gold, silver and other alloy effects that can be applied with hot foils. Your customers may be concerned about the environment when they hear the word foil. The technology used by Konica Minolta does not apply foils to the printed product: they merely serve as a carrier for the metalized pigments. Only these pigments are transferred to the varnish; the foil remains in the press and is recycled. This means that metalization does not produce harmful plastic waste, neither during production nor during disposal of the finished print products.

Surcharges pay off

MGI has made print finishing more affordable - and not just for high-end jobs. Yet there are clients who balk at the cost premium and the longer lead times compared to standard prints. "One of our customers decided for the more cost-effective screen printing of his catalogue. We then produced a sample with a 3D lacquer finish for the cover at our own expense. The customer was so enthusiastic about the proposal right away that he stopped the entire production at the screen printer and had us finish the printed sheets on the MGI JETvarnish 3D Evolution," reports an employee of druckpartner in Essen.

The example shows that when print customers have seen and felt the possible effects, they appreciate the innovative approach and are prepared to pay a premium for it. In the study "Beyond CMYK: The Use of Special Effects in Digital Printing, Keypoint Intelligence", European print buyers indicated that they are willing to pay a premium of up to 89 per cent for digital print enhancements over pure CMYK printing. From increased awareness at the POS to higher value creation for print businesses, enhancement is therefore a win-win development for the print industry.

Printed sounds and smells?

If you as a print service provider want to stand out from the competition, delight customers and thus leverage new sales potential, you cannot ignore digital coating technology. And who knows what emotional innovations the future will bring: perhaps new processes will make waves rustle in a travel brochure or we will be able to sniff out the smell of meals on menus. It sounds utopian, but that is what many experts used to think about the tactile print.