Increase efficiency, reduce production delays, minimise risk

Quality control in manufacturing, logistics, warehouse and similar environments is a critical but expensive and time-consuming process. In a complex or high-speed environment, human inspectors may struggle to keep pace, or may become distracted or fatigued — potentially leading to defects, anomalies and other issues being missed.

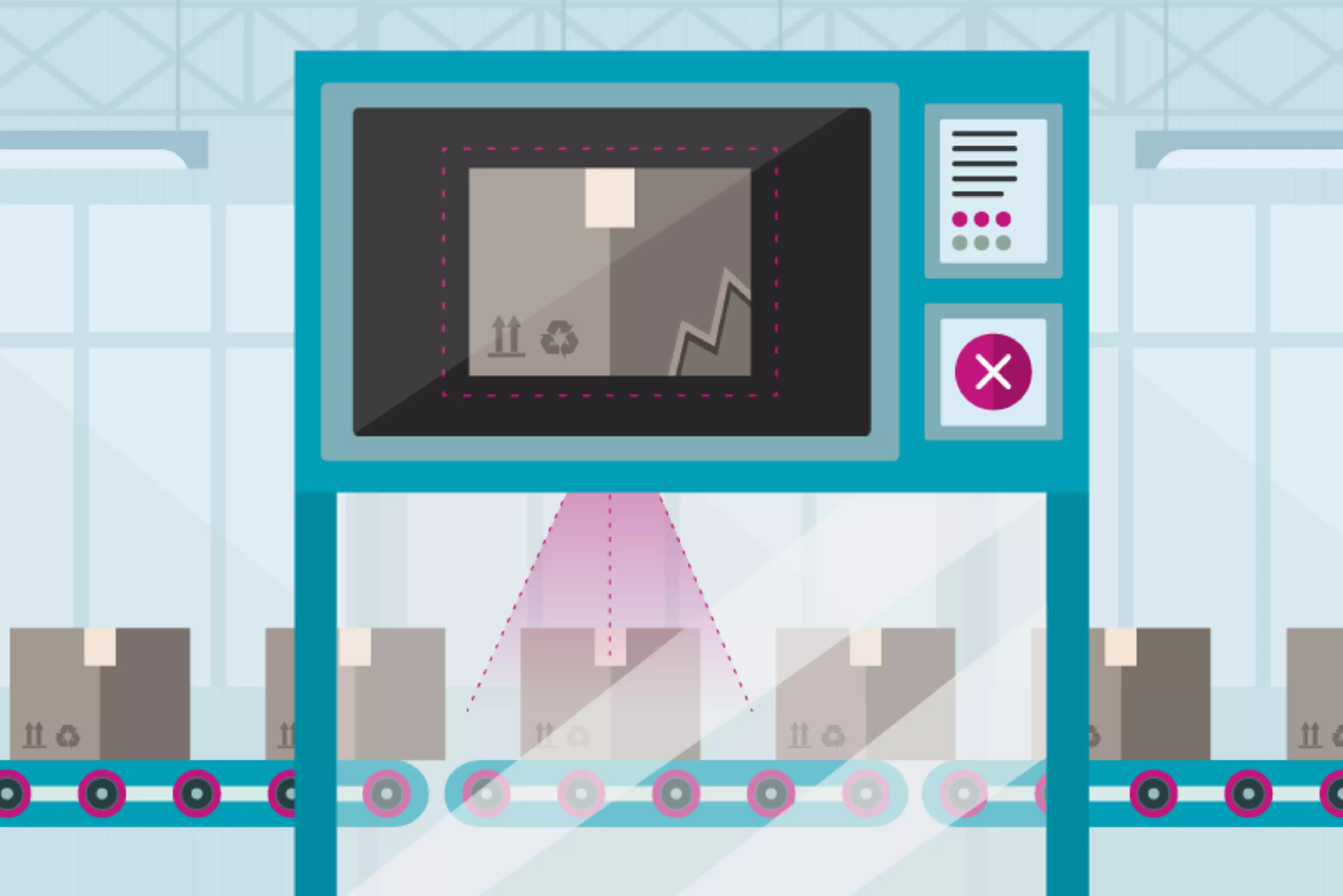

Maintain consistently high standards with video-based inspections

- Box defect detection in production and logistics environments, helping to ensure boxes are free from dirt and damage before being packed with goods for shipping. Defective boxes are automatically removed from the production line, and dirty boxes are sent for washing.

- Packaging inspection to check that vacuum packing is free from defects such as creases, splits and dirt; poor seams and seals; and badly printed or positioned labels.

- Continuous surface inspection to help ensure the integrity of sheet-form and other products that require a smooth surface free from defects like scratches, tears and glue leaks.

- Assembly quality inspection to guard against errors and defects in product or machine assembly such as missing, loose or badly fitted components.

Your benefits at a glance

Consistently high levels of visual quality inspection at all times

Alerting to anomalies or other issues enabling rapid automated or human intervention

Reduction in production downtime, manufacturing delays and excess costs caused by defective products

Increase in product or packaging quality, leading to benefits such as increased customer satisfaction and less waste

Easy-to-use dashboards support real-time action as well as historical analysis